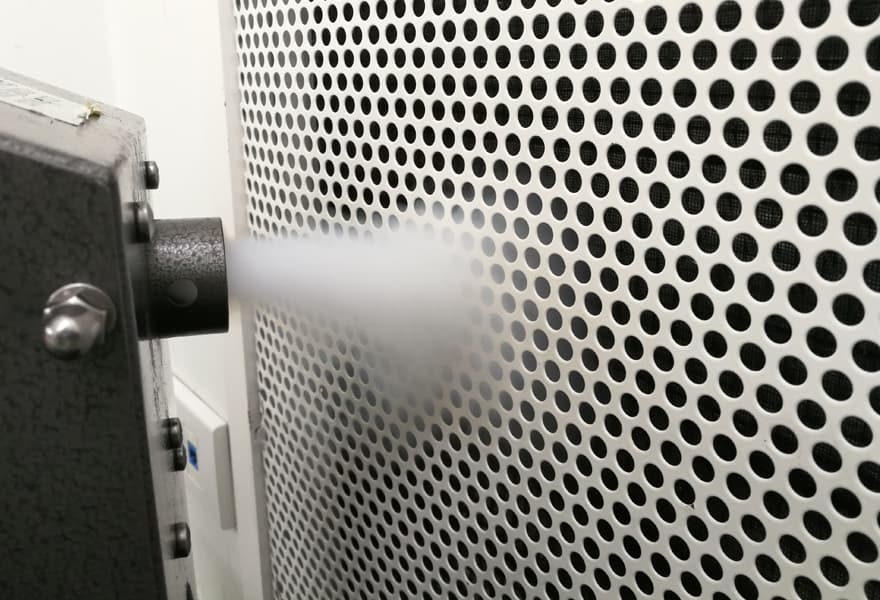

Importance of Unidirectional Airflow

Unidirectional airflow is vital in cleanrooms to prevent contamination by moving air in a single direction, away from sensitive areas.

Key benefits include:

- Reduces the risk of airborne particles settling on surfaces.

- Maintains consistent air pressure, crucial for cleanliness.

- Supports the efficiency of air filtration systems.